Tirzepatide API: The Foundation of an Innovative Diabetes Treatment

Tirzepatide is a novel medication used for the treatment of type 2 diabetes, and its active pharmaceutical ingredient (API) production process is crucial to ensuring the drug’s efficacy and safety. As a dual-action GLP-1 receptor agonist and GIP (glucose-dependent insulinotropic peptide) receptor agonist, the production of Tirzepatide API involves complex biotechnological processes and stringent quality controls. This article delves into the production process of Tirzepatide API, its technical requirements, market outlook, and its importance in the pharmaceutical industry.

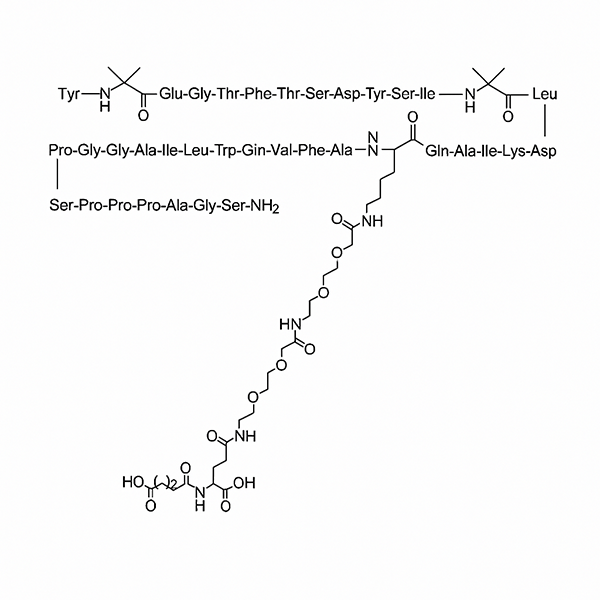

Overview of Tirzepatide API

Tirzepatide (chemical name: 6-amino-2-(4-amino-3,5-dimethylphenyl)-3-(1-hydroxyethyl)-1,3-dihydroimidazo[4,5-d]pyridazine-7-carboxylic acid) is a novel diabetes drug developed by Eli Lilly & Co., which acts as a GLP-1 receptor agonist and GIP receptor agonist. It helps control blood glucose levels by enhancing insulin secretion, suppressing appetite, and slowing gastric emptying. In clinical trials, Tirzepatide has shown significant effects in lowering blood sugar and promoting weight loss.

As a biologic drug, Tirzepatide API is primarily produced using recombinant DNA technology, where it is synthesized in host cells, such as E. coli or other expression systems. The production process involves multiple complex steps, from gene cloning to protein expression, purification, and final quality testing.

Tirzepatide API Production Process

-

Gene Cloning and Expression System Construction

The production of Tirzepatide begins with gene cloning. In this step, the gene encoding Tirzepatide is inserted into an expression vector, which will be introduced into host cells for protein expression. Commonly used host cell systems include E. coli, yeast, and mammalian cells. In Tirzepatide production, E. coli is often used as the host because it allows for high-yield protein expression. -

Protein Expression and Cultivation

Once the gene construct is complete, the transformed host cells are cultured in bioreactors under controlled conditions. These conditions include regulating temperature, pH, oxygen levels, and nutrient supply to ensure efficient protein expression. As the cells grow, they produce large quantities of Tirzepatide protein. -

Protein Extraction and Purification

After protein expression, Tirzepatide is extracted from the host cells and purified using various chromatography techniques. Common methods include affinity chromatography, ion exchange chromatography, and size exclusion chromatography. These techniques help remove impurities and ensure that the final product has high purity and quality. Since Tirzepatide’s activity depends on its specific structure, the purification process must ensure that its three-dimensional structure is not disrupted. -

Folding and Post-Translational Modifications

Tirzepatide is a peptide drug with a complex structure. After purification, the protein undergoes proper folding and post-translational modifications, such as glycosylation and the formation of disulfide bonds, to mimic the natural hormones’ functionality. These modifications are essential for the biological activity of the drug. -

Quality Control and Verification

The API of Tirzepatide undergoes rigorous quality control tests, including protein content determination, purity analysis, structural identification, and biological activity testing. Techniques such as mass spectrometry, high-performance liquid chromatography (HPLC), and enzyme-linked immunosorbent assay (ELISA) are commonly used for these analyses to ensure that each batch of the API meets the required specifications. -

Lyophilization and Packaging

To facilitate storage and transportation, Tirzepatide API is typically lyophilized (freeze-dried) to preserve its activity and increase its shelf life. The final product is then packaged into injectable formulations, ready for clinical use.

Technical Challenges in Tirzepatide API Production

The production of Tirzepatide API involves several technical challenges, including:

-

Choosing the Right Expression System: While E. coli is a commonly used host system, Tirzepatide’s complex structure and activity depend on precise folding and modifications. Therefore, optimizing the appropriate host cell and culture conditions is critical for efficient protein expression.

-

Protein Purification: Due to the complexity of Tirzepatide’s structure, any mishandling during the purification process could lead to the loss of its activity. Developing efficient purification techniques is essential to ensure the high quality of the API.

-

Folding and Post-Translational Modifications: Tirzepatide’s functionality is directly tied to its three-dimensional structure, so any errors in folding or modifications could affect its biological activity. Ensuring accurate structural modifications during production is crucial.

Market Outlook for Tirzepatide API

With the success of Tirzepatide in clinical applications, it is poised to play a significant role in the treatment of type 2 diabetes and beyond. The drug has also stimulated advancements in the biopharmaceutical industry. The production of Tirzepatide API presents significant opportunities for raw material suppliers and manufacturers who can meet the high standards of biologic drug production.

From a market perspective, Tirzepatide’s successful launch marks a breakthrough in biologics for diabetes treatment. As the global diabetes epidemic continues to rise, Tirzepatide’s dual-action mechanism makes it a highly sought-after treatment, with increasing demand for its API. Furthermore, as production techniques improve and the cost of manufacturing decreases, Tirzepatide could become more accessible to patients worldwide, especially in developing countries.

Conclusion

Tirzepatide API, as a novel biologic drug, plays a crucial role in the drug’s overall efficacy and safety. The production process involves complex biotechnological steps, including gene cloning, protein expression, purification, and quality control, to ensure that the final product meets the stringent standards required for clinical use. As the demand for Tirzepatide grows, both in terms of diabetes treatment and weight management, the drug will continue to drive advancements in the biopharmaceutical industry. With further optimization of the production process, Tirzepatide’s API could be more widely available, benefiting a larger number of patients globally and contributing to the ongoing fight against diabetes.

Post time: Feb-02-2026