China's Leading Manufacturers of Hormone Factories for Optimal Health

As a business owner keen on optimizing your supply chain, I understand the importance of finding reliable sources for vital components. When it comes to hormone factories, my experience tells me that China stands out as a hub for reputable manufacturers. The technology and expertise in these factories ensure that the hormone products meet stringent quality standards, suitable for various applications in the pharmaceutical and health sectors. I've partnered with some of the leading manufacturers in China, who specialize in producing a wide range of hormone products. Their commitment to innovation and quality control gives me confidence in the solutions we provide to our clients. By tapping into these hormone factories, you not only gain access to highly competitive pricing but also benefit from their ability to customize products to meet specific needs. Collaborating with a manufacturer in China means you're investing in the reliability and efficiency that your business deserves. Let’s connect and explore how these hormone factories can elevate your product offerings.

Hormone Factories Dominates Custom Solutions,

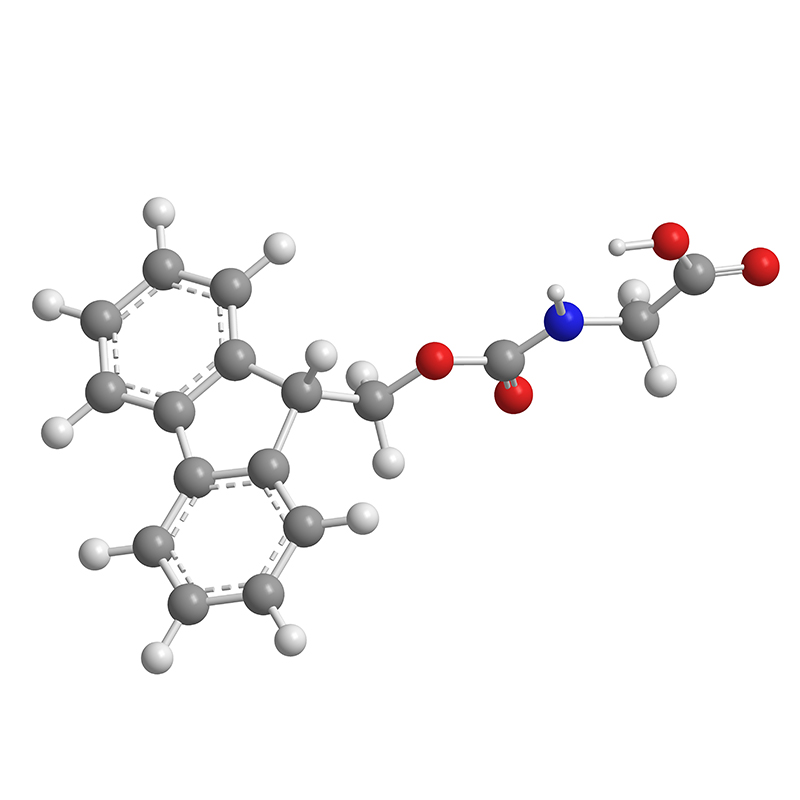

In today’s dynamic market, the demand for customized solutions in hormone production is on the rise. Companies are increasingly seeking tailored approaches that enhance efficiency while meeting specific regulatory standards. This creates a unique opportunity for businesses that specialize in developing bespoke hormone manufacturing processes, allowing them to stand out as leaders in this vital sector. By leveraging advanced technologies and innovative methodologies, these entities can provide solutions that not only address current market needs but also anticipate future demands. Custom hormone solutions facilitate a more agile response to industry changes. Suppliers are able to modify production techniques to align with evolving regulations and market trends, ensuring compliance while maximizing yield and quality. Furthermore, the ability to customize formulations enables clients to optimize their product offerings, catering to the specialized needs of various end-user segments. This adaptability is crucial in maintaining competitiveness and fostering long-term partnerships across the globe. Moreover, integration of cutting-edge technologies such as artificial intelligence and automation into hormone manufacturing processes has revolutionized the industry. By adopting these advancements, companies can enhance precision, reduce lead times, and lower production costs. This, in turn, contributes to greater availability of high-quality hormone products tailored to specific applications. As a result, global procurement professionals are keen to partner with suppliers who can deliver not just products, but comprehensive solutions that are aligned with their strategic objectives in an increasingly complex marketplace.

Hormone Factories Dominates Custom Solutions

| Custom Solution Type | Production Capacity (Units/Month) | Lead Time (Weeks) | Quality Assurance Method | Regulatory Compliance |

|---|---|---|---|---|

| Hormone Replacement Therapy | 1000 | 4 | ISO 9001 | FDA Registered |

| Custom Peptide Synthesis | 500 | 6 | cGMP | EMA Approved |

| Personalized Nutrition Formulas | 800 | 3 | HACCP | Nutraceutical Compliance |

| Bioidentical Hormones | 1200 | 5 | ISO 13485 | Health Canada Approved |

| Synthetic Hormones | 1500 | 8 | Good Laboratory Practices | TGA Compliant |

Related Products